We have many phone conversations each day when a client shares photo(s) of a stall front design. It is common that the client will like a particular design, but will experience "sticker shock" at the stall front's actual price.

As a luxury horse stall manufacturer, we completely understand this reaction. After all, our clients may not be familiar with our metals, fabrication, and the vast amount of engineering that goes into each stall. Before your next project, we would like to address cost drivers in horse stalls.

While we might work with clients with few budget constraints, we work with many clients who have a particular project budget. In either case, it is important that we educate our client to ensure they make the best decision to get the most value. To begin, two factors tend to the main cost drivers:

- Materials – Quantity and Cost

-

Labor – Welding & CAD Design

Sliding Stall Fronts

The first driver of cost is the distinction between a "kit" stall and a fully welded stall front. As mentioned earlier, a stall kit will include a welded door, track hardware, a latch, channels, and grillwork. This then requires significant labor and time onsite to build the stall. Cost is driven when the client chooses our popular fully welded system that includes a complete frame – removing the need to build and frame the stall onsite.

The next cost driver in a sliding horse stall is the addition of a yoke in the door itself. Yokes are the opening through which your horse can hang their head out. Our basic yoke is a v-shaped yoke opening that requires the steel tubing to be bent into shape. The cost can be driven further if a client chooses a hinged, drop down yoke that is popular in barns.

Drop down yokes are more cost intensive because of additional welding, hinge hardware, the addition of a stainless steel plunger latch, and an additional filled yoke piece. Drop down yokes are more cost intensive because of additional welding, hinge hardware, the addition of a stainless steel plunger latch, and an additional filled yoke piece.

European Stall Fronts

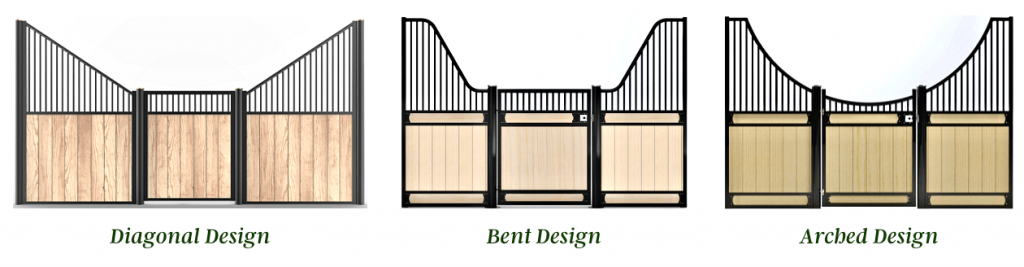

The first decision that drives cost in a hinged, European Stall Front ("Euro") is the height. We build both "low" Euros and high Euros. The main difference between the two is simply the height of the left wing, the door, and the right wing. The additional steel material is the main cost driver between the two types. The second decision that drives cost is the arch and radius bend of the left wing, right wing, door's top most tubing. Our Euros start with a straight diagonal design or bent design. Labor and specialized machinery is then required to further build larger swoops and arches.

The very last cost driver are the finishing touches such as end caps and finials. These can be made out of either aluminum, brass, or a powdered coated aluminum. Each cap or finial is hand polished in-house to ensure the most elegant finishing touch on your stall.

All Stall Fronts

There are decisions that impact both Sliding Stalls and Euros. A popular option is to place 1" round bars or steel mesh in the stall bottom. This bottom fill can be placed on either the door bottom or across the entire stall front bottom. This addition (i.e. 1" round bars or mesh) is one of the largest cost drivers for any stall. This is because this design uses a significant amount of steel.

Additionally, unlike many manufacturers, our mesh and bars are welded at every single joint for extra strength. When adding a mesh or bars, clients will also add a Shavings Guard to keep bedding inside the stall. This Shavings Guard can be either a steel sheet or a welded HVH that is ready for a wood piece. This is another cost driver to the stall due to the additional steel material and welding.

The above covers a good majority of things to consider, but it is not a comprehensive list of upgrades. It is true – if you can dream it, it can be done in most cases. We hope that the above allows you to understand how to choose a stall front that drives the most value for your barn.

Last but not least, feeding and watering options. Feed upgrades can include a feed hole opening, a grilled feed door, a revolving feed door, and other custom options. Each option requires CAD design, additional steel materials, welding, and hardware (i.e. hinges and latches). This is equally true for watering options such adding water spigots for water buckets or adding an integrated automatic waterer.

The above covers a good majority of things to consider, but it is not a comprehensive list of upgrades. It is true – if you can dream it, it can be done in most cases. We hope that the above allows you to understand how to choose a stall front that drives the most value for your barn.

Do you have any questions about what is the best horse stall design for your barn, horses, and budget? Our team would love to help answer any questions and make recommendations. Please kindly feel free to send us an email at sales@americanstalls.com or a call at (855) 957 8255. Alternatively, you can also complete a Contact Us Form.