- Home

- About Us

-

Custom Products

- Shop by Products

- Resources

- Contact Us

-

Sliding door Stall Fronts have become a popular choice for barns due to their ease of use and efficiency. Our Sliding Horse Stall Doors are designed to provide easy operation and excellent functionality.

As a leading manufacturer of Sliding Horse Stalls, we custom build our horse barn Stall Doors to fit your exact specifications, design goals, and lifestyle needs. Each sliding stall door is handcrafted with the finest raw materials and powder-coated to ensure longevity. Whether you’re building a new barn or upgrading your existing doors, you can count on American Stalls for high-quality, reliable, and stylish solutions.

At American Stalls, we understand that each barn requires a unique design approach to ensure ultimate personalization. To meet your needs, we offer a wide range of customization options for our horse barn stall doors, including:

Our expert team is here to help you navigate between the various customizations available in designing your horse stalls. Our horse stall equipment is custom built to order to fit your lifestyle needs. Rest assured, our American Stalls team will help you craft a barn environment that is stunning, warm and inviting, and safe. After all, home is where the barn is.

SPECIFICATIONS

FEATURES

HARDWARE

UPGRADE OPTIONS

Heavy gauge galvanized steel

Safely spaced bars

5 Year Limited Warranty

100% custom made in the USA

Custom Powder Coat Finishes: We offer our European Horse Stall Fronts in various finishes and Colors. Choose from a range of finishes and 10 different colors to suit your personal preferences and barn decor.

Feed & Water Options: The right feed and water options add ease and practicality to your daily routines. Choose from many designs such as built-in Grilled Feed Doors and more below:

Latch Options: Choose between various options. All hardware is constructed from heavy-duty stainless steel or brass.

Track System & Trolleys

Door Stop and Door Guide

Option 1: Flip Latch

Option 2: Pin Latch

Custom Yokes

Vented Mesh

4" Steel Frame

Custom Center Rail & Bottom Rails

Feed Hole Opening

Grilled Feed Door

Integrated Water Lines

Nelson Automatic Waterers

Whether you are building a new barn or renovating an existing barn, there are only two primary styles in horse stalls: Sliding Horse Stall Fronts, European Horse Stall Fronts (Hinged). In both styles, we can build them in two ways

Continue ReadingAs a horse lover, it is likely that you have visited dozens of barns. In those barns, we can guarantee that you have touch, felt, and seen numerous types of horse stalls. Across the United States, it is likely that you have seen more sliding horse stalls

Continue Reading

When planning your barn project, there are hundreds of micro decisions made on just about everything. This includes everything from the barn's structure to the horse stalls to the barn doors to the lighting fixtures to even security cameras.

Continue Reading

Dixon, MO

“The sales and shipping process was very easy! I actually reached out to the American Stalls team via Facebook to inquire about shipping times and they were very fast in their response and made sure my gates were sent out the next day. The product is high quality from the very start and has held up over time as well. When I first installed full size gates in my modest two stall barn, it instantly elevated the look of the stalls from a homemade project to professional job. The gates LOOK expensive. I was looking for a gate that was safe, well ventilated, and had a yoke for my horses’ heads to hang over. The full size gate ticked all the boxes. I love the construction, feel, and shine of the powdered coated steel, and they clean up so easily too! I couldn’t be happier with my gate choice.

The customer support also delivered high-quality service. They were very responsive both before and after the delivery. I had questions regarding shipping times before purchase and I received responses within 24 hours that put my mind at ease. They even worked with me to expedite my shipping in order to meet my desired timeframe. After delivery I received a lovely note in the mail thanking me for my patronage – a sweet touch that made me feel very valued!

I would recommenced American Stalls without a doubt! My AS stall fronts are beautifully constructed and always received compliments. I’m always sure to tell them where they came from and how much I love them! Every barn should have such high quality materials!

“We’ve been buying the Show Series portable stalls from American Stalls each year from the past four years. We’ve expanded our polo operations here in The Plains, VA and have needed more and more high-quality portable horse stalls. Our oldest stalls from American Stalls still hold up great even after years of usage. The newest portable stalls are (bought in May 2020) are especially well done and reveal a very high end product — including their welds, powder coat finish, and other key details. The newest stalls show American Stalls’ heavy investment in their commitment to their product quality. Thank you for a great product and a great customer experience!” – David McClung

Another happy horse (Phil) with his new American Stall half-sized stall gate here at Templar Farm LLC… Phil loves his stall guard. It is beautiful… These gates are very easy to install and only takes about 5-10 mins.”

Dear American Stalls staff, thank you so much for a quick and uncomplicated handling of our two orders of stalls! Shipping was fast and the product arrived at our property in promised high-quality condition. The entire Passion for Polo team and the horses are enjoying the stalls! Keep up the awesome work, American Stalls.

As the owner of a large miniature horse sanctuary, we are often finding our needs to be met, somewhat challenged. Most equine operations gear towards full-sized horses. We then have to either adapt products or have them customized to fit our needs. However, when we found ourselves in need of a quarantine stall with relatively little advance notice, American Stalls not only fit the bill, but came through with flying colors.

The turnaround time to receive our order was super quick.

During the sales process, American Stalls made the decision-making process very easy and guided us with great information every step of the way. We love the look of the stalls and the high-quality materials. For portable stalls, they surprised us by how sturdy they are and we expect to use them for years to come. Overall, the team at American Stalls delivered superior customer support. We loved meeting Yash in-person even as he traveled through the Midwest and we were proud to show him our new facility. Lastly, I absolutely recommend American Stalls to any equestrian facility who cares about quality and professionalism. We couldn’t be happier with our decision to purchase our stalls from them.

Our new Elite Series miniature horse portable stall is everything we had hoped it would be and more! Safe, secure, and stylish it is extremely easy to move and assemble- genius, really! No tools required, no small parts to get lost in the shuffle… We chose to have two yoked gates so that the children and seniors we visit off-site can access the minis from both sides of the stall. We have high standards to follow…and your American Stalls’ portable miniature unit earns blue ribbons all around.

Rose of Sharon Equestrian School

We just set up our new stalls for our 4-H Horse Camp and the kids and parents all loved them. They were very excited about the bars allowing for plenty of airflow as our old portable stalls were solid all the way to the top. The new stalls went together easier too! The presenters at the horse camp were so impressed they asked where we got the stalls from and are thinking about purchasing some of their own.

Working with American Stalls was a pleasure. The representatives were extremely cordial and responsive and attentive to our needs. They assisted us with all aspects of the transaction both professionally and thoroughly. Any inquiries made were met with a more than timely response.

The portable stalls assemble quickly, go together easily and have withstood a full year of shows with no visible wear and tear, a true testament to their durability. The stalls are both attractive and durable as has been proven by the number of horses that have been in and out of the stalls. Their website contains loads of pictures, and the information is very representative of the product; a good quality product with good customer service.

Erie County Fairgrounds

Thank you for your help finding the right gates for our older barns. You sent great sample photos and reassured us the gates are sturdy and well built. The gates arrived well packaged with no damage. The design is excellent and they installed more easily than any other stall gates we’ve had. The quality is excellent and promises years of safe, happy horses. Thank you!

Fieldstone Riding Club

Yes, we proudly serve personal and commercial facilities throughout North America, Canada, and Mexico. As such, you can purchase our stall equipment from anywhere in these countries, and we will have it sent to you.

Our dedicated logistics team manages transportation and helps ensure the equipment is delivered to your barn quickly and efficiently

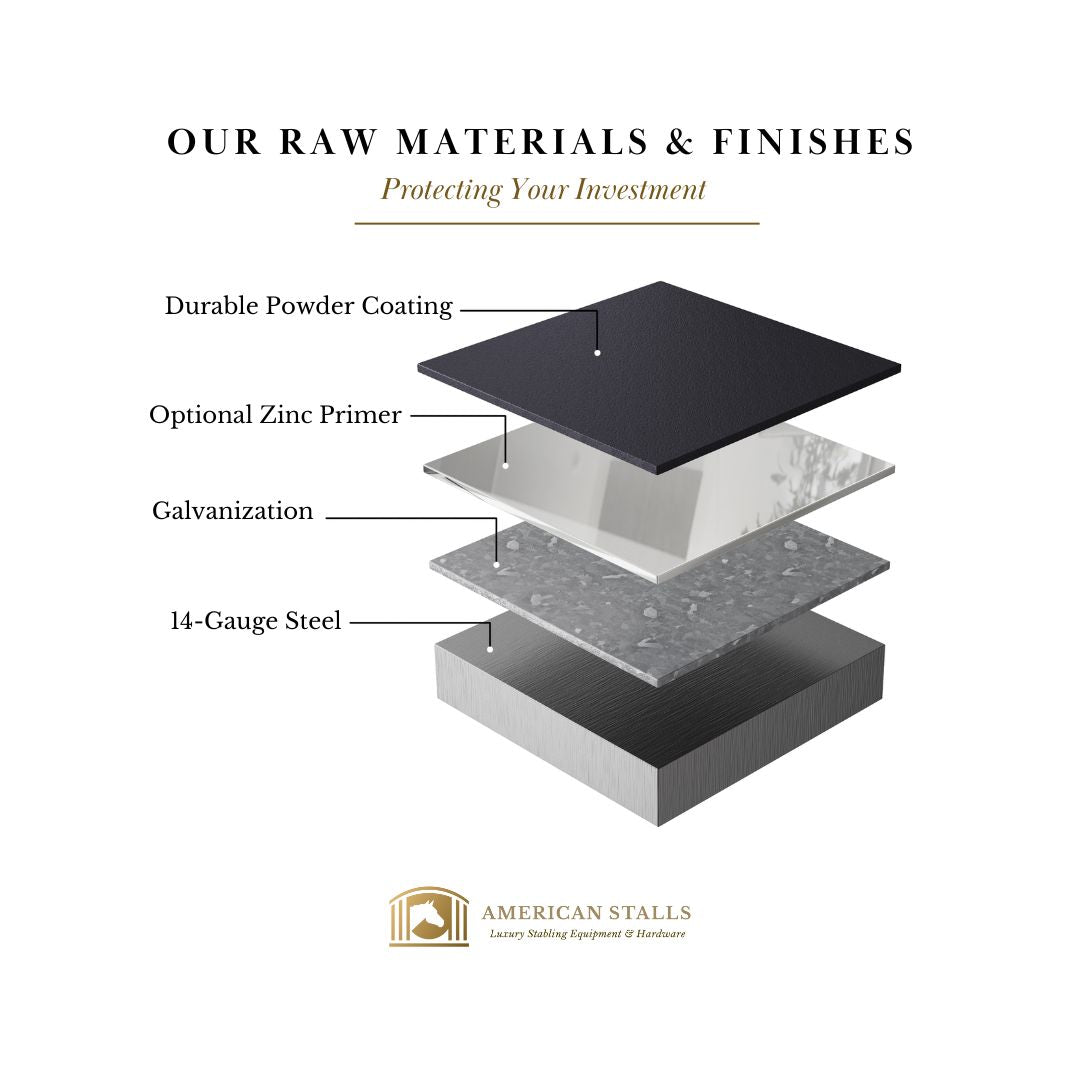

The gauge refers to the specific thickness of the steel. It is indicated by a measurement in inches or millimeters, whereby the gauge number increases as the thickness of the steel decreases. We offer products with different gauges. However, we typically use 14-gauge United States steel for our horse stall sliding doors.

All of our American Stalls products are built with longevity in mind. We use only the very best raw materials, including pre-galvanized steel for our structural components. We then exclusively use pre-galvanized steel, stainless steel, and/or aluminum on all hardware (i.e. hinges, latches, bolts, etc).

Our pre-galvanized steel frames, tubing, and hardware all undergo a strict quality control process before powder coating. For example, we use a zinc-prime paint coat on all welds for any projects going to high salt exposure areas such as coastal Florida.

We believe this is a significant differentiator where we take multiple steps to clean and prime our pre-galvanized products prior to powder coating. We then powder coat each component from experts who have years of experience. Lastly, we utilize an industry-leading TGIC-polyester-based powder coat finish that is tested for ultimate performance. Rest assured, your American Stalls products will stand the test of time.

Yokes are very popular across our Sliding Horse Stall Door designs. The Yoke is a custom cut out on the top half of a horse stall door.

This Yoke "opening" offers your horse the opportunity to stick its head into the aisle to see fellow horses and people. A yoke might not be the best option for each horse since temperaments and facilities will vary. That being said, we offer many options in yokes.

Our Open Yoke is the most popular among clients. This is simply a cut-out in the shape of a v-shape or a rectangle. This is open at all times and is best suited for well-mannered horses that get along with other horses and riders.

We also offer our clients the ability to close their yokes with Yoke-Fill Pieces and Hinged Fold-Down Systems. Both options allow for added functionality for our Sliding Horse Stalls.

This is a great question! Many Sliding Horse Stalls on the market are difficult to move as the years go on. This is because the track systems might not be well-suited for a barn environment where dust builds up. To prevent this, our track systems feature a self-cleaning design, which ensures no build-up within the track that might obstruct movement.

Secondly, most track systems on the market use cheaper plastic trolleys (also known as rollers). These plastic trolleys are low quality and will deteriorate as they continue to roll against dust, debris, and other build-up in the track. Instead, we use heavy-duty Delrin balls as our trolleys, which ensure your Sliding Horse Stalls will effortlessly glide for years to come.

We design our sliding horse barn doors to offer easy installation. Plus, our knowledgeable team provides detailed installation instructions to make the process easier and ensure you follow the proper steps.

We offer our clients two options: our Flip Latch and our Pin Lock Latch. Our Pin Lock Latch is our best-selling latch, but our flip latch is sometimes used in facilities that have a personal preference. Our Pin Lock Latch features the highest quality materials, including 304 stainless steel and aluminum. These materials ensure durability, strength, and overall longevity.

We always recommend our Sliding Horse Stalls and Pin Lock Latch because they promote safety in your barn. For example, in the case of an emergency, our design allows you to quickly unlock each stall door — allowing you to go from one stall to the next.

You absolutely can purchase the horse stall door, grillwork, and hardware— instead of the entire Stall Front System. We wrote a helpful article to help provide more clarity to clients about the possibilities. Read more here at Fully Welded Horse Stalls versus Kit Horse Stalls.

Compared to European (hinged) stall fronts, sliding stall fronts allow our clients to save valuable space. The sliding stall door slides against the stall front panel or existing horse stall front. Hence, the door doesn’t swing outward into the barn aisle like a hinged horse stall door. This space-saving feature makes sliding doors a perfect fit for busy facilities, including horse boarding barns, training barns, and large venues.

We offer a five-year limited warranty on our sliding horse stalls, which is effective for workmanship. We offer an industry-leading lifetime warranty on our track system.

Our clients often need equipment to unload our horse barn stall doors. You may require a forklift or similar machinery that can handle the products' load capacity. Our team will gladly communicate the freight protocol and the equipment required based on your specific order to ensure you are well-prepared for the delivery.

For sliding horse stall equipment, we require a forklift (or similar equipment) that has the ability to handle 5,000 lbs with 6 feet forks.