- Home

- About Us

-

Custom Products

- Shop by Products

- Resources

- Contact Us

-

European stall fronts, also known as Euros or hinged horse stalls, are the epitome of elegance and functionality. These stall fronts are meticulously designed to offer your horses comfort and security while contributing to the overall aesthetic appeal of your equestrian facilities. At American Stalls, we design and construct luxury hinged horse stall doors from premium raw materials to provide quality and durability.

Since our European horse stalls are custom built to order, we do not offer standard designs. Our skilled artisans handcraft all European stalls and equipment to deliver functionality while capturing the style's distinct appeal. You can choose a classic Western aesthetic or personalize the stall fronts with additional features such as aluminum caps or brass finials.

As a leading custom horse stall manufacturer, our European stall fronts have become synonymous with quality, sophistication, high performance, and safety. We pride ourselves in providing premium horse stall solutions tailored to your needs and lifestyle. Plus, our team can help you select the best design options for your facility. Contact us online to request an estimate for our hinged horse stall doors today!

Our expert team is here to help you navigate between the various features and options you may want to include into the design of your horse stalls. Our horse stall equipment is made to order and built to fit your lifestyle needs. Rest assured, our American Stalls team will help you make a barn environment that is stunning, warm and inviting, and safe. After all, home is where the barn is.

SPECIFICATIONS

FEATURES

HARDWARE

UPGRADE OPTIONS

Heavy gauge galvanized steel

Safely spaced bars and mesh

5 Year Limited Warranty

100% custom made in the USA

Custom Powder Coat Finishes: We offer our European Horse Stall Fronts in various finishes and Colors. Choose from a range of finishes and 10 different colors to suit your personal preferences and barn decor.

Feed & Water Options: The right feed and water options add ease and practicality to your daily routines. Choose from many designs such as built-in Grilled Feed Doors and more below:

Latch Options: Choose between various options. All hardware is constructed from heavy-duty stainless steel or brass.

Adjustable Hinges

Plunger Latch

Mounting Channel

End Caps & Finials

Vented Steel Mesh on Bottom

1" Round Bars on 2.5" OC Bottom

Polished End Caps & Finials

Custom European Swoops & Curves

Feed Hole Opening

Grilled Feed Door

Integrated Water Lines

Nelson Automatic Waterers

Horse stalls are one of the first things that our clients begin to think about when they plan their upcoming barn project. Chances are, you know exactly the look you'd like in your barn. In the world of horse stalls, there are thousands of stall styles.

Continue ReadingStep inside an elegant black and white barn situated in Southern Florida.Behind every new horse barn is an equestrian who has been dreaming about the moment when their barn is finally ready. For Melina of MPM Sport Horses, the wait is over. She designed her modern, European inspired barn

Continue Reading

If you are like us, it's likely that you have spent time on Instagram, scrolling endlessly through elaborate horse barns. Chandeliers. Beautiful wood panelling on the walls and ceilings. Elaborate horse stalls. While many barn interiors may seem out of reach, the reality is that you too can create

Continue Reading

Dixon, MO

“The sales and shipping process was very easy! I actually reached out to the American Stalls team via Facebook to inquire about shipping times and they were very fast in their response and made sure my gates were sent out the next day. The product is high quality from the very start and has held up over time as well. When I first installed full size gates in my modest two stall barn, it instantly elevated the look of the stalls from a homemade project to professional job. The gates LOOK expensive. I was looking for a gate that was safe, well ventilated, and had a yoke for my horses’ heads to hang over. The full size gate ticked all the boxes. I love the construction, feel, and shine of the powdered coated steel, and they clean up so easily too! I couldn’t be happier with my gate choice.

The customer support also delivered high-quality service. They were very responsive both before and after the delivery. I had questions regarding shipping times before purchase and I received responses within 24 hours that put my mind at ease. They even worked with me to expedite my shipping in order to meet my desired timeframe. After delivery I received a lovely note in the mail thanking me for my patronage – a sweet touch that made me feel very valued!

I would recommenced American Stalls without a doubt! My AS stall fronts are beautifully constructed and always received compliments. I’m always sure to tell them where they came from and how much I love them! Every barn should have such high quality materials!

“We’ve been buying the Show Series portable stalls from American Stalls each year from the past four years. We’ve expanded our polo operations here in The Plains, VA and have needed more and more high-quality portable horse stalls. Our oldest stalls from American Stalls still hold up great even after years of usage. The newest portable stalls are (bought in May 2020) are especially well done and reveal a very high end product — including their welds, powder coat finish, and other key details. The newest stalls show American Stalls’ heavy investment in their commitment to their product quality. Thank you for a great product and a great customer experience!” – David McClung

Another happy horse (Phil) with his new American Stall half-sized stall gate here at Templar Farm LLC… Phil loves his stall guard. It is beautiful… These gates are very easy to install and only takes about 5-10 mins.”

Dear American Stalls staff, thank you so much for a quick and uncomplicated handling of our two orders of stalls! Shipping was fast and the product arrived at our property in promised high-quality condition. The entire Passion for Polo team and the horses are enjoying the stalls! Keep up the awesome work, American Stalls.

As the owner of a large miniature horse sanctuary, we are often finding our needs to be met, somewhat challenged. Most equine operations gear towards full-sized horses. We then have to either adapt products or have them customized to fit our needs. However, when we found ourselves in need of a quarantine stall with relatively little advance notice, American Stalls not only fit the bill, but came through with flying colors.

The turnaround time to receive our order was super quick.

During the sales process, American Stalls made the decision-making process very easy and guided us with great information every step of the way. We love the look of the stalls and the high-quality materials. For portable stalls, they surprised us by how sturdy they are and we expect to use them for years to come. Overall, the team at American Stalls delivered superior customer support. We loved meeting Yash in-person even as he traveled through the Midwest and we were proud to show him our new facility. Lastly, I absolutely recommend American Stalls to any equestrian facility who cares about quality and professionalism. We couldn’t be happier with our decision to purchase our stalls from them.

Our new Elite Series miniature horse portable stall is everything we had hoped it would be and more! Safe, secure, and stylish it is extremely easy to move and assemble- genius, really! No tools required, no small parts to get lost in the shuffle… We chose to have two yoked gates so that the children and seniors we visit off-site can access the minis from both sides of the stall. We have high standards to follow…and your American Stalls’ portable miniature unit earns blue ribbons all around.

Rose of Sharon Equestrian School

We just set up our new stalls for our 4-H Horse Camp and the kids and parents all loved them. They were very excited about the bars allowing for plenty of airflow as our old portable stalls were solid all the way to the top. The new stalls went together easier too! The presenters at the horse camp were so impressed they asked where we got the stalls from and are thinking about purchasing some of their own.

Working with American Stalls was a pleasure. The representatives were extremely cordial and responsive and attentive to our needs. They assisted us with all aspects of the transaction both professionally and thoroughly. Any inquiries made were met with a more than timely response.

The portable stalls assemble quickly, go together easily and have withstood a full year of shows with no visible wear and tear, a true testament to their durability. The stalls are both attractive and durable as has been proven by the number of horses that have been in and out of the stalls. Their website contains loads of pictures, and the information is very representative of the product; a good quality product with good customer service.

Erie County Fairgrounds

Thank you for your help finding the right gates for our older barns. You sent great sample photos and reassured us the gates are sturdy and well built. The gates arrived well packaged with no damage. The design is excellent and they installed more easily than any other stall gates we’ve had. The quality is excellent and promises years of safe, happy horses. Thank you!

Fieldstone Riding Club

We are located just outside Washington D.C., but our customers are all over the world. We custom build and ship our custom horse stalls across the world.

Our expert logistics team can coordinate the best transportation to help your stall equipment reach your barn via the quickest, most efficient method. This applies to any domestic deliveries within the United States and even for international deliveries across the world.

The actual thickness of the steel sheet is indicated as a unit of measurement referred to as “gauge.” The rating for steel gauge may seem backward: The smaller the number, the thicker the steel. For example, 14-gauge will be thicker than 16-gauge.

We use a variety of different gauges on our products. However, our European Horse Stall Front systems use 14-gauge American steel for the steel framing and the steel tubing. We then use heavy-duty 10-GA (Schedule 40) round posts. We then use a variety of metals, such as stainless steel and aluminum, on our hardware to ensure ultimate longevity and strength. Rest assured, your American Stalls equipment is built to last.

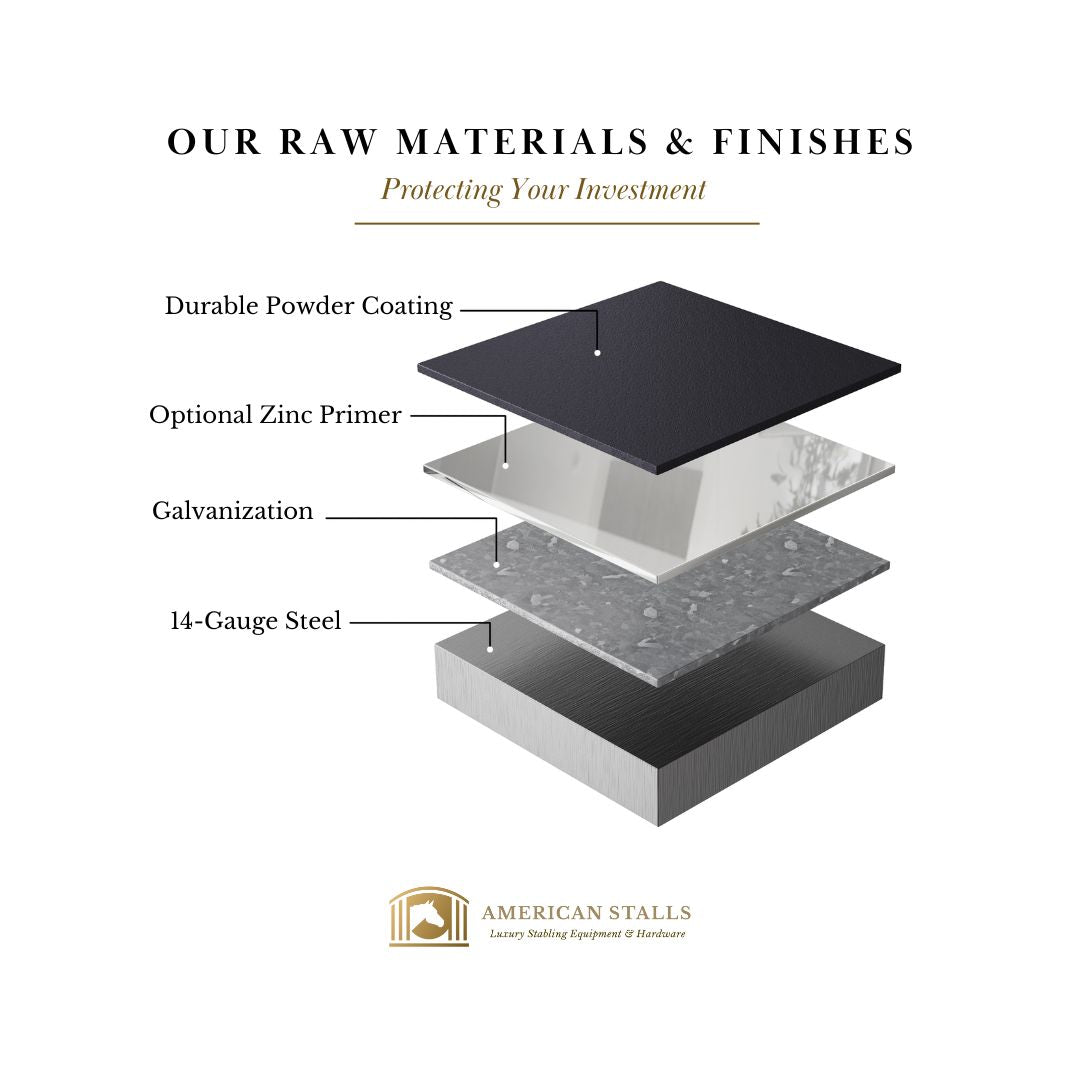

All of our American Stalls products are built with longevity in mind. We use only the very best raw materials, including pre-galvanized steel, for our structural components. We then exclusively use pre-galvanized steel, stainless steel, and/or aluminum on all hardware (i.e. hinges, latches, bolts, etc).

Our pre-galvanized steel frames, tubing, and hardware all undergo a strict quality control process before powder coating. For example, we use a zinc-prime paint coat on all welds for any projects going to high salt exposure areas such as coastal Florida.

We believe this is a significant differentiator where we take multiple steps to clean and prime our pre-galvanized products prior to powder coat. We then powder coat each component from experts who have years of experience. Lastly, we utilize an industry-leading TGIC polyester-based powder coat finish that is tested for ultimate performance. Rest assured, your American Stalls products will stand the test of time.

We use our Plunger Latch on all of our European Horse Stall Fronts. This Plunger Latch is built in-house in our facility to ensure ultimate quality control.

Our Plunger Latches, most commonly, feature a 304 stainless steel knob and striker plate. Our knob ensures a beautiful aesthetic, while our striker plate ensures no scratches when closing your door. Our Plunger Latch's knob can also be upgraded to other precious metals such as brass (upon request).

We prioritize simple, functional design in all of our products. That means simplicity and practicality for the end user. That also means simple products that are easy to install by our clients, general contractors, and builder partners.

Once you take delivery on your custom European Horse Stall Fronts, your Project Manager will share precise, detailed Installation Instructions. Our Instructions include in-depth visuals, videos, and helpful instructions. We are also always available via phone call or FaceTime to assist our clients with any real-time questions.

Yes, our European Stall Fronts require a concrete base to be anchored upon.

Our European Stall Fronts comprise of 3 core components – a left wing, door, and right wing. The left and right wings are welded to round posts that feature 6" baseplates. These baseplates include pre-drilled holes through which you must anchor your posts to the concrete for structural integrity.

On very custom occasions, we are able to manufacture a system that does not require a full concrete curb. Contact an American Stalls Project Manager to discuss further options.

Our European Stall Fronts are exceptional for the vast majority of barns and breeds. We routinely build our European Horse Stall Fronts for larger breeds that compete in dressage and hunter jumper circuits.

That being said, the choice in horse stall front is a personal decision based on your facility, its foot traffic, your horses, their dispositions, and more. For example, we recommend our "High" European Stall Fronts for horses that need a little bit more containment. Our high Stall Fronts feature wings that are 7' to 8' tall as opposed to our "Low" European Stall Fronts that swoop drastically at the wings.

Contact your American Stalls Project Manager for more 1:1 guidance regarding your project and horses.

We offer a five-year limited warranty on our European Horse Stalls which is effective towards workmanship.

Yes, our clients do often require equipment to unload your American Stalls purchase from the delivery truck. Our team will communicate the necessary freight protocol and required equipment based on the purchased products.

For European Horse Stall equipment, we require a forklift (or similar equipment) that has the ability to handle 5,000 lbs with 6 feet forks.