Most horse stall products fall under the following 2 categories:

- Horse Stall Kits

- Fully Welded Horse Stall Panels

A client's construction skills, intended design, and budget will often determine which of the two styles are right for your project.

The Horse Stall Kit

Horse stall kits are sold in a variety of "pieces" that a client will then assemble themselves. A horse stall kit includes components such as:

- Grillwork (also known as "grates")

- U-Channels that hold the tongue and groove lumber in place

- Wall stiffeners (also known as wall braces) for horse stall partitions

- The hinged or sliding horse stall door

- Stall door hardware – Hinges for a hinged stall door and a track system for a sliding stall door

Horse stall kits tend to be more cost-effective when compared to fully welded horse stall panels. Kit stalls are more cost-effective because there is less welding and labor involved during the manufacturing process.

That being said, horse stall kits do require more time during the actual installation process. This added time can sometimes drive up the cost if a client is using a contractor to install the horse stalls.

Kit Stall Components | Explained

U-Channels

U-Channels are vertical steel channels that hold the horse stall's tongue and groove lumber in place. They come in two lengths including 4' and 8'.

4' U-channels are often used for stall front sections and horse stall partitions – allowing for grill sections on top. In contrast, 8' U-channels are often used for full wood partitions between horse stalls.

Grillwork

Grillwork is also known as a "horse stall window" or "grate." Grillwork is usually installed along the top halves of stall fronts and stall partitions. Our grillwork include the following standard specifications:

- 14-GA United States steel used throughout the frame and bars

- All steel bars are 1" in diameter

- All steel bars are placed 2" apart

Similar to our fully welded stall panels, our grillwork uses concealed welding. This means that our steel bars are punched through the steel frame and channels. The bars are then welded on the inside. All welds are then out of sight on the underside of the channels. This is a small detail, but adds to the longevity and durability of your horse stall.

Wall Stiffeners

Wall stiffeners, otherwise known as wall braces, add more rigidity to your stall walls. They achieve this by connecting the tongue and groove lumber boards together. Wall stiffeners are most commonly used for horse stall partitions, but can also be used for stall fronts.

All wall stiffeners are constructed of heavy-duty 14-GA United States steel and come with proper fasteners.

Stall Doors

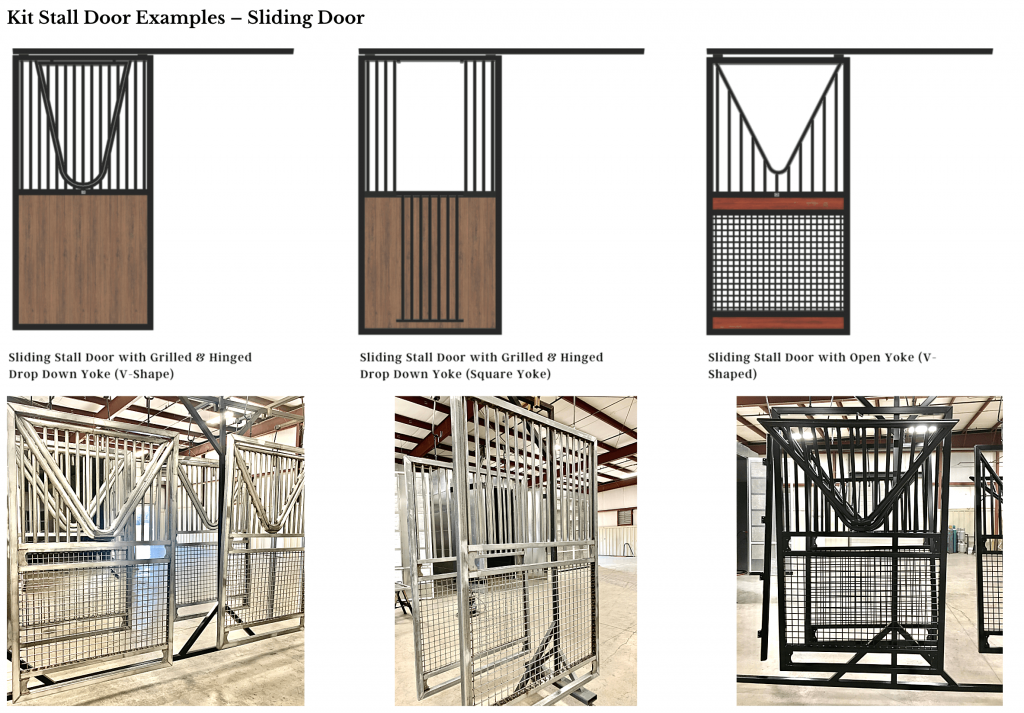

There are two primary types of stall doors including hinged stall doors and sliding stall doors.

Hinged stall doors have a beautiful look, but require more aisle way space as the door swings outwards. Sliding horse stall doors are safer since they slide alongside a stall front. This means that there is one less protruding element in a horse barn's aisle. When deciding on kit stall, the stall door is often the one place where the client spends time on their decision.

The Fully Welded Horse Stall System

In contrast to kit horse stalls, fully welded horse stall systems are panel systems that are prefabricated steel frames.

This means that the stall panels are ready to install the minute they deliver to your farm. Once unloaded from the flatbed truck, fully welded panels are ready to attach to existing barn support columns or assemble to create a freestanding horse stall structure.

Pre-welded panels are often pricier during the sales process when compared to kit horse stalls. This is because there is a significant amount welding and fabrication during the manufacturing process. Pre-welded horse stall panels do help save time, labor, and cost during installation though. Fully welded stall panels can drop the installation time from 10+ man hours for a kit horse stall to about two man-hours for a fully welded system. This cost consideration brings the cost comparison to be much closer at the end.

In addition, pre-welded frames, partitions, and horse stall fronts add the benefit of greater strength because of additional welding across all components. Lastly, fully welded horse stalls also come in two predominant styles:

You will use your stall front and stall door thousands of times – opening it, closing it, leaving it open, and everything in-between. That’s why it’s so important to make a well-informed decision. As with any option, each stall front type comes with its pros and cons.

Hinged Stall Fronts & Stall Doors

Hinged stall doors are traditionally more common than sliding doors.

That being said, hinged stall doors tend to be less practical than sliding doors because they must swing outwards into the barn aisle. This means that your barn aisle must be fairly wide – even more so if you have two rows of stalls directly facing each other.

If you are considering hinged stall doors, we suggest to consider the following:

- Aisle Width: The aisle should be wide enough to allow for the hinged door to safely open and close. Rule of thumb is a minimum 12-14' wide aisle.

- Aisle Leveling: The aisle needs to be tempered and leveled. This is crucial since the bottom of a stall door can get stuck on uneven flooring. This is why we recommend that, if you choose a hinged door, to allow for a few inches of clearance between the barn floor and the bottom of the stall door. If your barn aisle is full of hills and bumps, we would advise against a hinged horse stall door.

Horse Sliding Stall Fronts & Stall Doors

While sliding doors don’t have the open appearance of a hinged stall door, they are still great investments for your horse stalls for many reasons. Sliding doors are a fantastic addition to any barn as they save space since the door doesn’t swing outward into the barn aisle. This space-saving feature makes sliding doors a perfect choice for especially busy facilities.

Most importantly, we tend to prefer sliding doors on stall fronts when possible. We prefer sliding doors over hinged doors primarily for safety reasons – including:

- A hinged door can get caught by the wind. This could injure a horse or human if the stall door is left open in the aisle.

- A hinged door needs to be closed when the horse is note in the horse stall. Therefore, the handler has one more additional action to do when leading a horse out of its stall to close or open a latch. Ideally, a safe design ensures that least amount of handling and steps.

- If a hinged door is closed, a horse can potentially get loose from the stall if the door does not latch for some reason.

- When horses are turned out and a sliding door has been left open, a human can simply look down the aisle and tell who is out and who is not.

- As noted above, when you are leading the horse back into the stall and the sliding door has been left open, there is less action involved to ultimately close the stall door.

- Lastly, sliding doors are recommended from a fire safety standpoint. In the case of a fire, you have very little time to make crucial, life-saving decisions. In this case, you simply pull the pin latch or push up the latch and slide open the door as you move to the next stall.

Horse Stall Partitions

Similar to a horse kit stall, fully welded stalls consist of the stall front and the stall partitions.

Fully welded stall partitions, otherwise known as divider walls, serve the same function as a stall kit partition. Clients often choose the fully welded frame as it provides a more finished look to your horse barn's interior. Fully welded partitions also serve an added function for breeding purposes. Unlike a kit partition, we can add a hinged component to a stall partition and allow it to function as a removable divider to make a larger foaling stall.

In any case, you should factor in the following elements when making your decision on the partition design:

- The climate in your area

- The temperament of your horses

- The operational style of your facility

- The primary use of the stalls

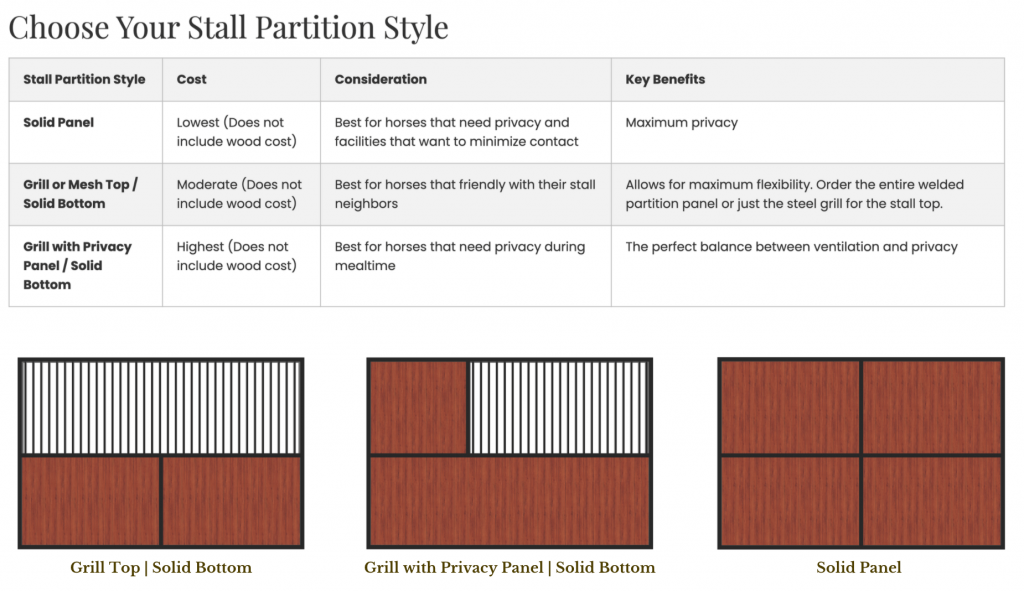

There are 3 common designs in fully welded stall partitions including:

- STEEL GRILL TOP / SOLID BOTTOM – This particular stall partition offers ventilation and socialization through the grills on top. We recommend this design to most clients who’d like to maximize ventilation and socialization.

- GRILL TOP WITH PRIVACY PANEL / SOLID BOTTOM – This style provides the best of both worlds from the other two options. This stall partition style offers some cross ventilation while still providing great privacy for the horses.

- SOLID PANEL – Solid partition panels can be created from wood or masonry. This design helps provide ultimate privacy. This particular design is well-suited for larger operations where you’d like to limit socialization and contact among stall neighbors.

Do you have more questions to determine what is best for your farm and barn? If so, please feel free to give our team a call and we would love to help in any way. You can contact us at (855) 957-8255.